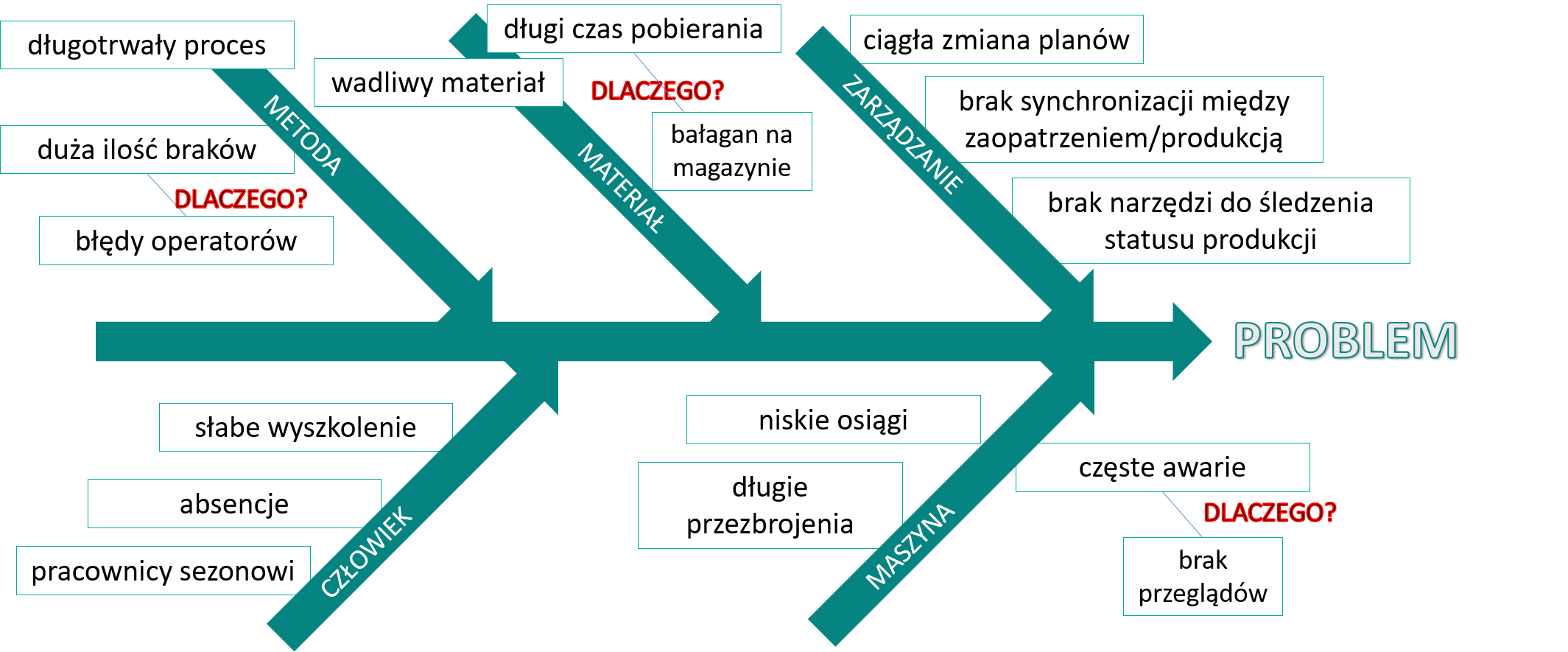

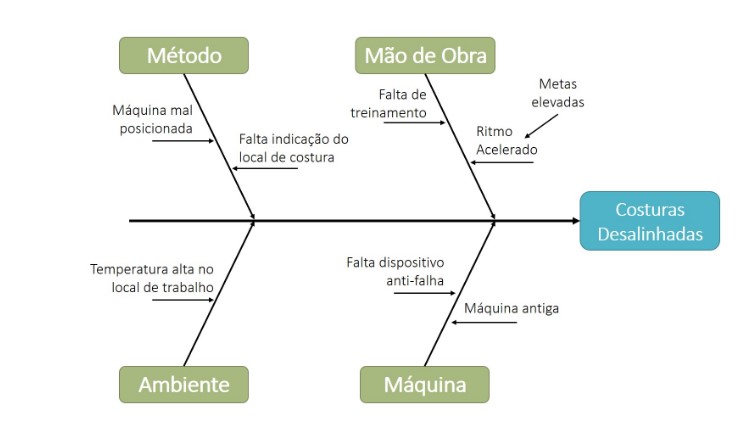

De belangrijkste grondoorzaken worden inzichtelijk en het probleem kan dan uiteindelijk doelgericht opgelost worden. After the team has exhausted the brainstorming session, the team will then boil down the many factors to the vital few factors from which they will place their monitoring, controlling, and improvement methodologies. Door pragmatisch naar het Ishikawa diagram en de 6M’en (categorien) te kijken kun je een eventuele gevonden de fout(en) opbreken in een of meerdere stukjes, hierdoor maak je het zelf gemakkelijk om het probleem te ontleden. Typically, they will use a Fishbone Diagram along with brainstorming to gather these ideas. A fishbone or cause and effect or Ishikawa diagram is a brainstorming tool to. Ishikawa as the 4M’s (Machine, Material, Method, Measurement) and over time it evolved to including the human element and noise factors affected by the forces of nature (e.g., humidity, vibration, temperature, etc.) The team uses these 6M’s as memory joggers to focus on when they are identifying as many of the factors that might influence the process as possible.

Use: There may be thousands of factors that directly affect or interact with each other to affect the outcome of some desired result(s) of a process. Door pragmatisch naar het Ishikawa diagram en de 6M’en (categorien) te kijken kun je een eventuele gevonden de fout (en) opbreken in een of meerdere stukjes, hierdoor maak je het zelf gemakkelijk om het probleem te ontleden. Sometimes referred to as the 5M- or 6M-chart.

These are referred to as the 6Ms Methods, Machines. Ishikawa states the 6 Ms (also known as the 5 Ms and 1 P) as: Man, Machine, Material, Method, Measurement, Mother Nature. Ishikawa diagram examines a broad set of possible causes of a problem for the issue to be analyzed. Man (in the generic sense), Machine, Material, Method, Measurement, Mother Nature are the categories/the components of variation that contribute to the production of some desired result. Ishikawa diagram - a chart that can be used to systematically gather the problem causes of quality defects. Those six elements 5 Ms and on P (or 6Ms) influence variation in all processes manufacturing or not.

0 kommentar(er)

0 kommentar(er)